Flexible packaging in Japan is changing fast.

Food companies want lighter packs. Retailers want simple materials that are easier to recycle. Packaging makers are updating machines and removing extra layers. The whole market is moving in one direction: simpler, cleaner, and more efficient packaging.

Japan has always expected very high packaging quality. Packs must look clean, protect food well, and last through long supply chains. Now the market also expects packaging that fits modern life. People want packs that go straight into the microwave. They want packs that open easily. And they want less waste.

Because of this, Japan is slowly moving away from heavy, multi-layer films. Companies are choosing mono-material films, new high-barrier designs, and heat-resistant packs for ready meals, soups, noodles, bento dishes, and frozen food. Flexible packaging is not being replaced. It is being updated for the future.

A Big Shift Toward Simpler Films

For many years, Japanese packaging used complex laminations. These packs were strong, but they were hard to recycle. They used several layers, including PET, aluminium, nylon, and special adhesives. These films worked well for snacks, sauces, and ready meals, but they created a recycling problem.

Today the industry wants films that are easier to process.

This change is coming from three places. New rules encourage companies to reduce waste. Retailers want lighter packs that seal better. Consumers want packaging that is simple and creates less rubbish.

Japanese converters such as Toppan, DNP, Toyo Seikan, Rengo, and Oji are responding. They are creating new mono-material films that perform almost the same as older, more complex films. These new films are strong enough for Japanese standards, which are some of the highest in the world.

Mono-Material Films Becoming The New Normal

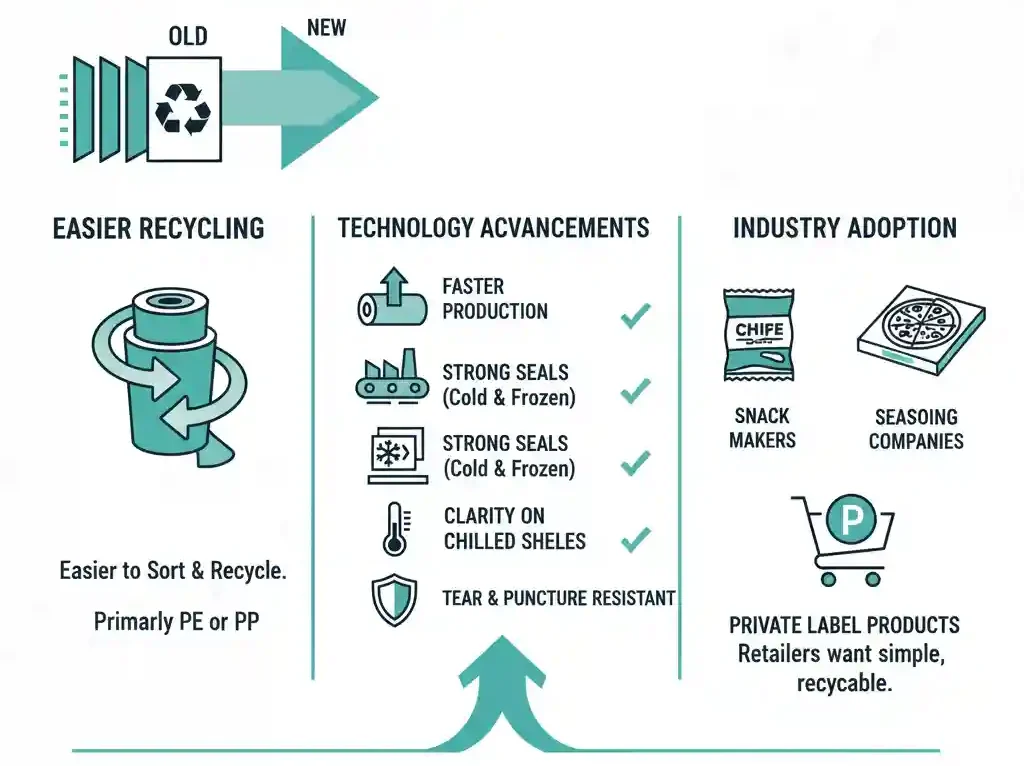

Mono-material films are easier to sort and recycle. They mostly use PE or PP. In the past, these films did not have enough barrier strength or sealing power. Today the technology is much better.

Factories can run these films faster. Seals hold better in cold and frozen supply chains. The films stay clear on chilled shelves, even when the temperature changes. They also resist tears and punctures during transport. Because of these improvements, more companies are switching to mono-material designs.

Snack makers, frozen-food producers, and seasoning companies are already moving in this direction. Private-label products move even faster because retailers want simple, recyclable structures.

High-Barrier Pouches Still Very Important In Japan

Japan needs high-barrier packaging more than many other countries. Food safety and freshness are major priorities. Many products rely on barrier pouches, especially miso, sauces, coffee, rice, and retort meals. These packs must control oxygen, moisture, and aroma.

In the past, many pouches used aluminium foil. Now converters are replacing foil with advanced coatings. These new films still protect food well, but they are lighter and easier to recycle.

Retort pouches are also changing. These packs must survive high heat during sterilisation. New designs are thinner, more flexible, and sometimes partly transparent. This helps shoppers see the product more clearly. Converters are reducing film thickness while keeping the same safety level. This supports sustainability goals and lowers cost.

Microwave-Safe Packs Becoming Standard In Ready Meals

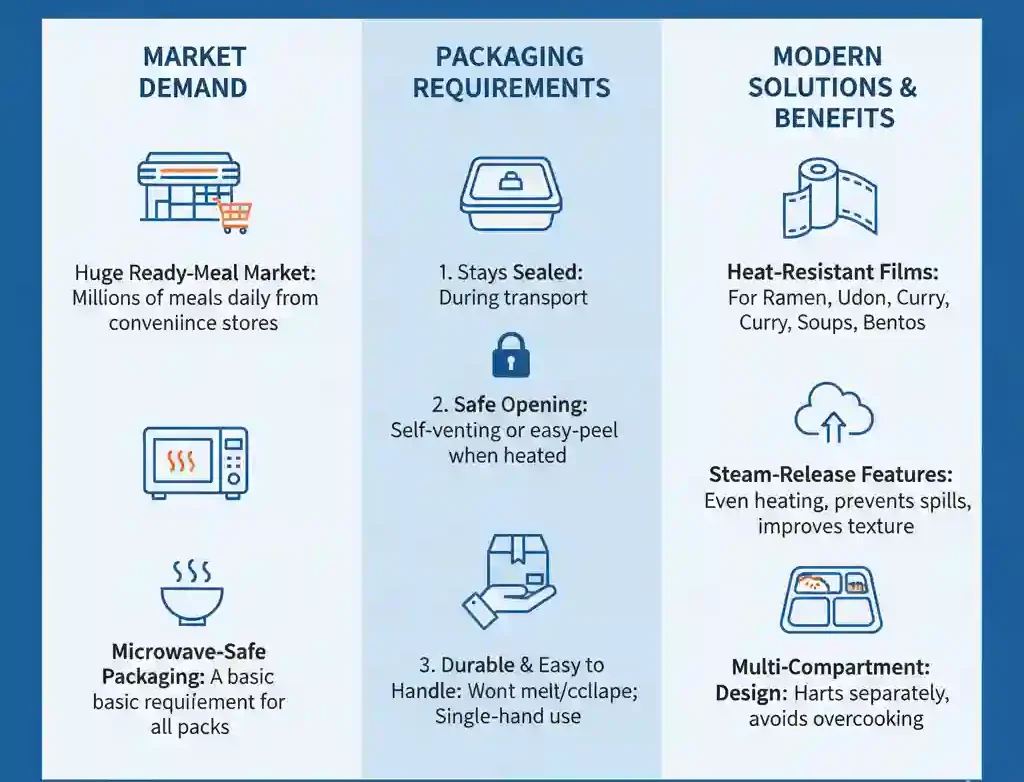

Japan’s ready-meal market is huge. Convenience stores sell millions of meals every day. Because of this, microwave-safe packaging has become a basic requirement.

These packs must stay sealed during transport, but they also need to open safely when heated. They cannot melt or collapse in the microwave. They must be easy for customers to handle with one hand.

Modern heat-resistant films can handle direct microwave heat. They are used for ramen, udon, curry rice, soups, and premium bentos. Some packs include steam-release features so the food heats more evenly. This stops spills and improves the eating experience.

Many retailers also sell bento meals with separate compartments. Each part of the meal heats differently, so the packaging must support this. The design keeps textures better and avoids overcooking.

How Retailers Shape Packaging In Japan

Retailers in Japan have a very strong influence on packaging. They do not just buy products. They set clear rules for how packaging should look and perform.

Supermarkets and convenience stores ask suppliers to reduce materials, improve seals, and make recycling instructions easier to understand. Private-label products must follow strict guidelines. This pushes suppliers to update their packaging quickly.

Shelf presentation is also important in Japan. Retailers expect clear windows, clean printing, and stable pouch shapes. Packs must look neat in the fridge or shelf. These visual standards guide many packaging decisions.

Convenience stores such as 7-Eleven, FamilyMart, and Lawson go even further. They need packaging that works with their national delivery systems. Meals travel long distances every night. Packs must survive this without leaking or breaking.

Exports Push Packaging Standards Higher

Japan exports many packaged foods. These include noodles, snacks, confectionery, sauces, and ready meals. Export buyers, especially in Europe, now expect more recyclable films, lighter packs, and clearer labels.

Because of this, Japanese converters design films that meet international rules. Many companies now use the same pack structure for both domestic and export markets. This lowers cost and keeps quality consistent.

Japan’s Ageing Population Changes Packaging Needs

Japan has a large older population. This affects packaging design. Many older shoppers want packs that open easily. They prefer small portions and lightweight materials. They also want clear fonts that are easy to read.

Flexible packaging supports these needs well. Companies are making more single-serve pouches and easier-open seals. This trend is growing every year.

Factories Are Becoming More Automated

Packaging converters in Japan are modernising their factories. Many lines now use sensors and cameras to check seals and print quality. Robots handle parts of the filling process. Machines can change film rolls faster.

These upgrades help when switching to new materials. They also reduce mistakes and make production more stable.

Regulation Supports the Shift

Japan’s Plastic Resource Circulation Act encourages companies to cut waste and use materials that can be recycled more easily. It does not ban materials, but it guides companies toward simpler designs. Local recycling systems are also improving. Together, these changes support the move toward mono-material flexible packaging.

What Comes Next

Japan’s flexible packaging market is moving in a clear direction.

More companies will adopt mono-material films.

More products will move away from aluminium foil.

Microwave-safe designs will keep improving.

Retailers will continue to push for lighter packs.

Recycling systems will slowly get stronger.

Flexible packaging will remain important in Japan. People rely on fast, convenient meals. Retailers need packs that can travel long distances overnight. Brands need reliable shelf life. What is changing is not the purpose of flexible packaging, but how it is made. Japan is choosing simpler materials, cleaner designs, and smarter engineering.

The future is lighter, easier to recycle, and better suited to modern life.

Editor’s Note: This article is based on real industry trends in Japan’s packaging market.

Information reflects public updates from major Japanese converters, retailers, and food manufacturers. No invented data has been used. The focus is on clear, simple explanations of how mono-material films, high-barrier packs, and microwave-safe formats are growing across Japan’s food and ready-meal categories.

For accuracy, the article follows the general direction of Japan’s Plastic Resource Circulation Act, retail private-label guidelines, and common packaging practices in convenience stores and supermarkets across the country.